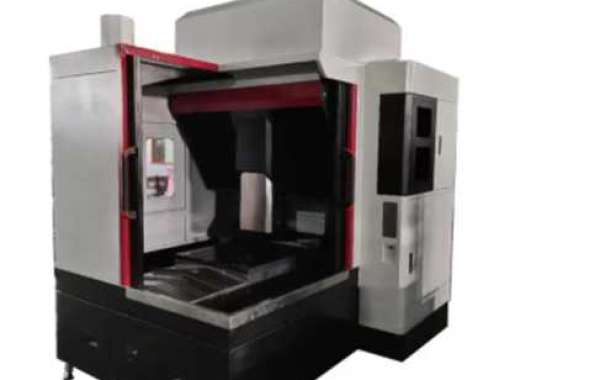

Sinker EDMs are suitable for hardened conductive products and complicated section information that are challenging to device by various other techniques. While the electric discharge machining procedure is typically slower compared to traditional milling, it excels at creating little deep functions that are past the ability to mill to repeatable high precision.CNC EDM Machine

EDM devices accelerate the trigger disintegration procedure by enhancing purging and particles elimination with a boost in the Z-Axis cycle leap price 4 times much faster and velocity price 30 times much faster compared to previous innovation. CNC EDM MachineThe improvements to flexible leap purging and the all new greater power completely electronic ES200A generator produce much faster Sinker EDM machining rates with considerably reduce electrode use.

The rate of production get rid of RAM EDMing has enhanced significantly throughout the years. On older devices, high electrode use frequently made it required to harsh out tooth dental caries previously doing RAM EDMing. However with solid-state power materials and costs electrodes, its feasible to utilize no-wear setups to harsh and after that complete in one configuration.Orbiting in ram EDM enables a roughing electrode to frequently be utilized likewise for completing. Formerly, it was typical to require several electrodes to harsh a cavity and after that more to complete it. Orbital courses help in purging the cavity by producing a pumping activity. The electrode can reduced not just all-time low however likewise along the sides leading to a a lot higher surface area location being machined at the same time.

Orbital courses feasible in ram EDM consist of down machining, vectorial machining, directional machining, cone-shaped machining, straight worldly machining, round machining, helical machining, concave round machining, and convex round machining. Electric discharge machining (EDM), likewise called trigger machining, trigger deteriorating, pass away sinking, cable shedding or cable disintegration, CNC EDM Machineis a steel construction procedure where a preferred form is acquired by utilizing electric discharges.Product is eliminated from the work item by a collection of quickly repeating present discharges in between 2 electrodes, divided by a dielectric fluid and based on an electrical voltage. Among the electrodes is called the tool-electrode, or just the device or electrode, while the various other is called the workpiece-electrode, or work item.